The Properties of Indonesian rattan Indonesia | 09/12/2023

THE PROPERTIES OF INDONESIAN RATTAN

By:

Jasni and Krisdianto

Forestry Engineering and Forest Product Processing Research Center (FEFPProc) ,Bogor, Indonesia

There are four basic properties of rattan which have significant role on its processed products. The four properties are i.e. those of anatomy, physics, mechanics, and durability ( Jasni et al., 1997).

1. Anatomical Properties

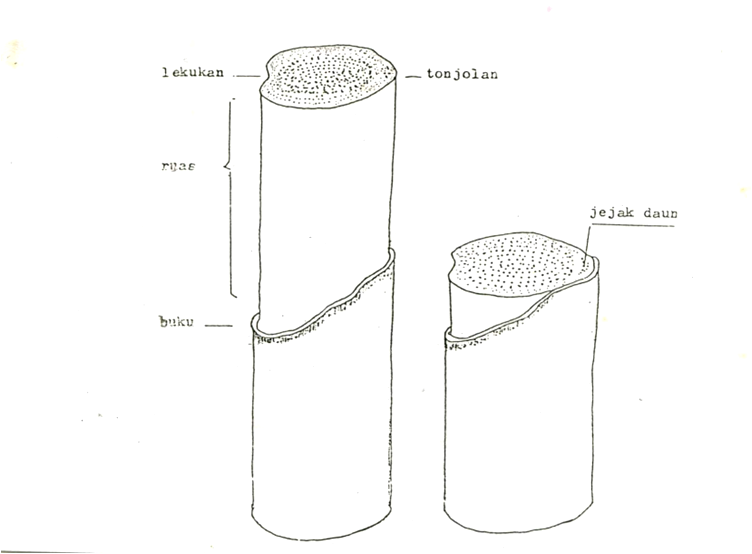

Generally, there are two kinds of rattan anatomical properties, those are macro and micro. Macroscopically, rattan cane consists of massive cylindrical stem with internode every 10 – 50 cm. Stem diameter varies from 0.7 to 5 cm.

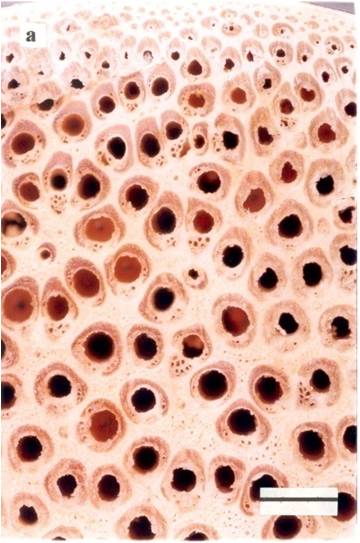

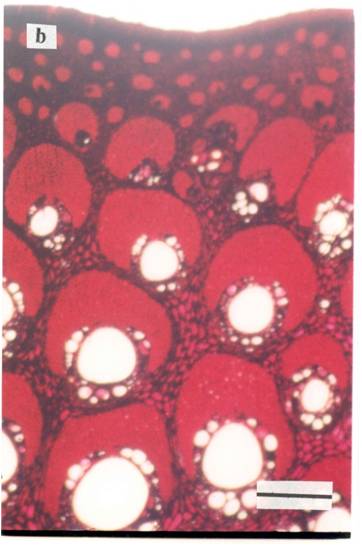

a. scale 1 mm b. Scale 250 μm

Remarks : 1 = Vascular bundles, 2 = Ground parnechymatous tissue

Figure 2. Transversal surface of stem of rattan balubuk (Calamus burchianus Becc.)

Size of pores and fiber wall dimension can determine the resistance of rattan against degrading organisms attack. In addition, rattan fibers provided mechanical strength to the rattan (Rachman, 1996 Bhat dan Thulasidas, 1993). Jasni, et al. (1997) reveal that average fiber-wall thickness of longa (Korthalsia junghunii Miq.) rattan was 4,98 micrometers, while those of seuti (Calamus ornatus Bl.) and bubuay (Plectocomia longate Bl.) rattans were 3,91 micrometers and 3,49 micrometers, respectively. The difference in these varying wall thicknesess can affect significantly the strength of rattan itself.

2. Chemical Properties

As a lignocellulosic material, chemical contents of rattan are important for its utilization. Generally, rattan stem consists of holoselulosa (71 – 76%), selulosa (39 – 58%), lignin (18 – 27%) and longa (0,54 – 8%) as well as starch (18 – 23%). Chemical contents of 16 rattan species shown in Table 5. Cellulose and lignin contents correlate significantly with rattan strength. In this regard, cellulose can contribute to the tensile strength, of rattan due to presence of strong covalent bonds in the pyranose rings and between glucose units of the cellulose polymer chain. Consequently, the higher the cellulose content the stronger the modulus of rupture of rattan. Almost similar to cellulose content, lignin also provide significant strength of the rattan. Likewise, the greater the lignin content, the stronger the bonds between fibers in rattan.

Please download the attachment for chemical properties of rattan in Indonesia

3. Phisical and Mechanical Properties

Physical and mechanical properties is the most important properties of rattan. The physical properties of rattan are closely related to its specific gravity. The higher the specific gravity, the greater the content of ligno-cellulosic substances resulting in the thicker fiber wall, thereby increasing the strength of rattan (Brown et al, 1952). Mechanical properties of certain material are associated with its ability to resist force or external load, and for woody or ligno-cellulosic fibrous materials, affected by thickness of fibre wall (Haygreen and Bowyer, 1982 in Subekti, 1995). The two main criteria as used in evaluating the mechanical properties of ligno-cellulosic fibrous material (including rattan) are modulus of elasticity (MOE) and modulus of rupture (MOR). Elasicity of rattan is positively correlated with its qualities (Rachman 1996).

Rattan that over 18 mm in diameter classified as large diameter rattan. The strength of those rattan is important for main structure in rattan furniture.

Refferences:

Bhat, K.M.n and P.K. Thulasidas. 1993. Anatomy and identification of South Indian rattan (Calamus sp.) IAWA Journal 14(1):63-76.

Brown, K.M., P.K. Panshin and C.C. Forsaith. 1952. text Book of Wood Technology. Vol.II. Mc Graw Hill Book. Co. New York.

Jasni. A. Basukriadi, dan P. Kramadibrata. 1997. Anatomi dan kandungan kimia batang beberapa jenis rotan.Jurnal Ilmiah Biodiversitas Indonesia. FMIPA Universitas Indonesia.1(1):37-47.

Mandang, I.Y. dan S.Rulliaty. 1986. Anatomi Batang Rotan. Himpunan Diktat Kursus Penguji Rotan, Jilid I. Sirkulasi terbatas. Pusat Penelitian dan Pengembangan Hasil Hutan, Bogor.

Rachman ,O. 1996. Peranan sifat dasar terhadap perilaku elastoplastisitas rotan. Thesis S3. Program Pasca Sarjana. IPB. Tidak diterbitkan.

Subekti,D.E. 1995. Pengaruh sifat anatomi terhadap sifat fisik dan sifat mekanik beberapa jenis rotan. Thesis S1. Fakultas Kehutanan. IPB. Tidak diterbitkan.

Yudodibroto, H. 1984. Anatomy, Strength properties and utilization of some Indonesian rattan. In : Proc. Rattan Seminar, Kualalumpur. The RIC (1985) : 117 – 121

| NO | FILE NAME | DOWNLOAD |

|---|---|---|

| 1 | PROPERTIES_OF_INDONESIAN_RATTAN.pdf | Download |